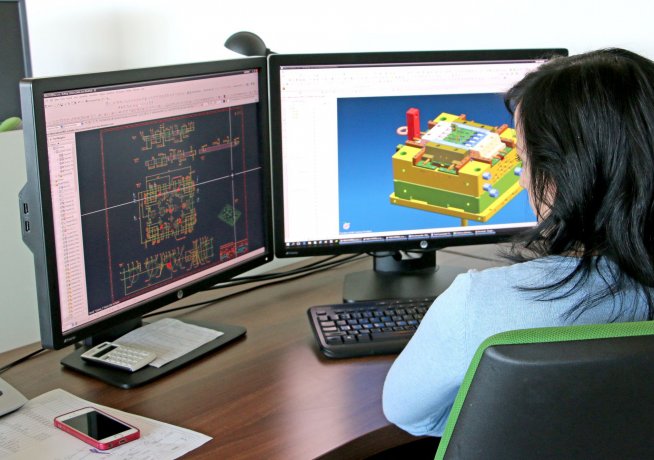

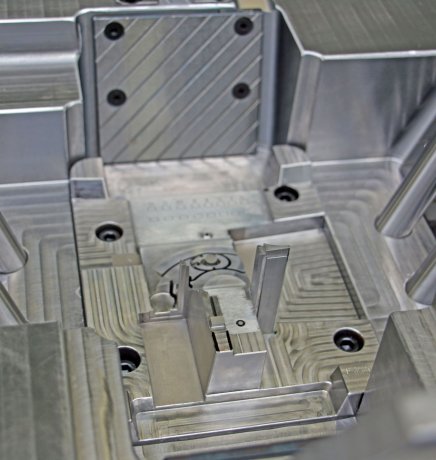

Company fortell s.r.o. (Ltd.) is active in the fields of moulding of plastic parts, stamping of metal parts and manufacturing of injection moulds for plastics. Established in 1995 as a technical design office. The company has expanded over the years, setting up its own stamping department, tool shop and moulding department. In 2008 we moved into our current state-of-the-art production facility and in 2016 we completed building of a new assembly and storage hall. The total area of the company increased to 8.300 sqm. Currently we employ approximately 220 people.

OUR GREATEST STRENGTH

All services under one roof

The biggest advantage we offer is in being able to provide all services under one roof. We can help our customers with product development, in-house mould design, mould-making in the tool shop and mass-production of plastic and metal components in our moulding and stamping departments. We have a well-coordinated team of highly qualified and experienced professionals who represent the finest Czech engineering traditions. We supply a range of custom-made products to many high profile companies across several sectors (electrical, automotive, consumer goods and medical equipment industries) located all across Europe, Latin America, USA and Japan.