We are a solely Czech company with its own design department and tool shop, which is at hand to our domestic and European customers in the development of plastic or metal parts and during the production of prototype or serial moulds and tools without the risk of logistically demanding Asian cooperation.

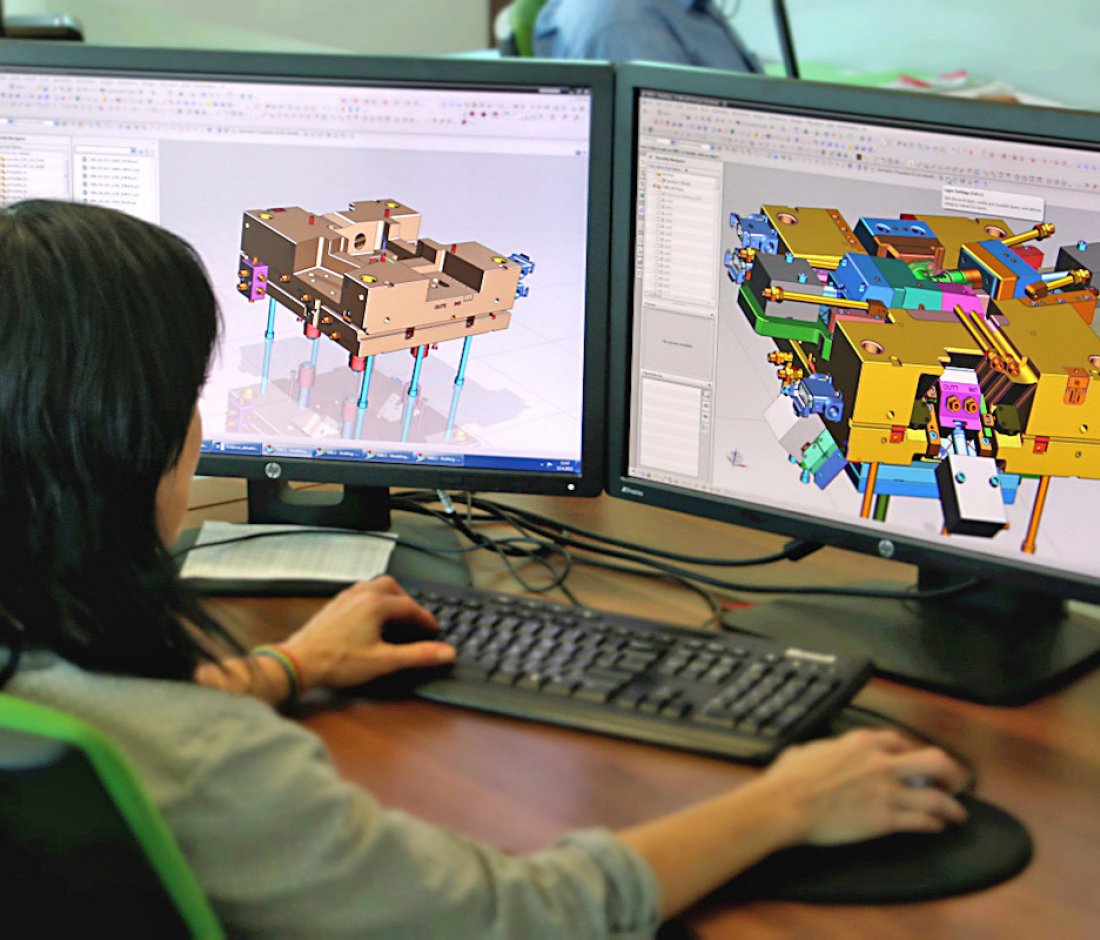

Development and design

We provide our customers with assistance in the development of plastic and metal parts using our almost 30 years of experience in this field as well as modern technologies such as CAD / CAM system NX (Siemens), mould-flow system SIMCON Cadmould or 3D printing technology FFF (Raise3D PRO2) and SLA (Creality LD-006). After finalising the feasibility study, we will prepare a 3D and 2D design of a prototype or serial mould or stamping tool.

Production of injection moulds

Once the design is completed, the project passes to our own tool shop, where we have a stable team of specialists. We have many years of experience in the production of prototype and serial moulds with hot runner systems and cold inlets, moulds for overmoulding, moulds with hydraulic and pneumatic systems, stack moulds, moulds for 2K injection and moulds for thin-walled moulded parts.

Spare parts manufacturing

We also focus on the flexible production of spare parts and components for injection moulds, stamping tools, including their frames, or assembly machines. We can also offer the production of measuring and control jigs according to customer specifications.

Tool shop capabilities

- Programming and modelling in NX Siemens

- CNC 3-axis milling up to 1650 x 810 x 810 mm, load max. 2500 kg

- CNC 5-axis milling up to 800 x 800 x 550 mm, load max. 1400 kg

- Wire cutting up to 500 x 350 x 256 mm

- EDM countersinking up to 600 x 400 x 450 mm

- EDM burning up to a workpiece height of 250 mm

- Surface grinding up to 1200 x 630 x 480 mm

- Classic lathe turning up to 190 mm in diameter

- Horizontal drilling up to 670 x 750 x 450 mm

- Coordinate measurement up to dimensions 800 x 1000 x 700 mm

- Multisensor optical measurement up to dimensions 400 x 500 x 350 mm

- Fitting and assembly of moulds, tools and jigs weighing up to 4500 kg.

- Laser welding